What Lasertec offers you

With virtually limitless laser possibilities combined with various measurement capabilities including a SEM in our 425 m² Lasertec is for more than 25 years a trusted partner. With Reliability you can expect from a company with over 26 laser workstations, but with eagerness of a small company.

Laser Ablation

A material removal process with localised interaction allowing a very thin layer of gold of 1µm to be evaporated in 5 steps. Thanks to our ultra-fast lasers, we have an ablation process with a minimal heat impact. This enables the drilling of burr-free holes in various materials, as well as the removal of thin layers as accurate as 0.2 µm on large surfaces.

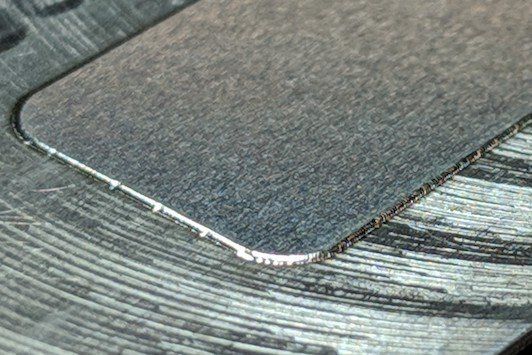

Laser Welding

High-brightness fibre lasers in combination with high-end positioning enables us to weld accurately in position and depth. We weld stainless steel to platinum, wire to sheets, and from 50 µm up to 1.5 mm thick. Better control of the laser energy and an accurate spot position allows us to create a micro welding process capable of strongly and precisely joining very thin layers of material together.

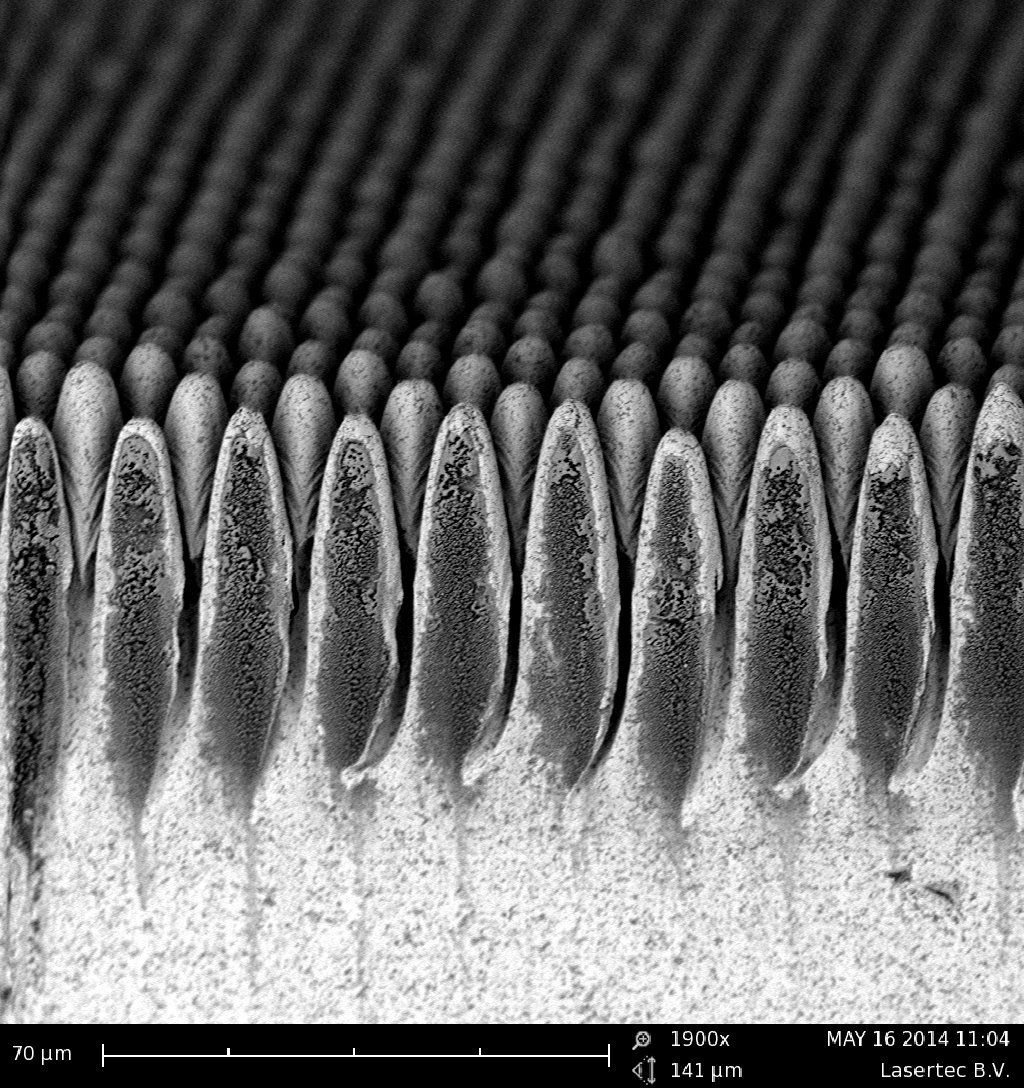

Laser Structuring

Selective aesthetical sandblasting, friction reduction, physical restructuring, optical effects, and gluing optimisation are just the tip of the iceberg to the endless possibilities of applications to reorganise surface structure with a state-of-the-art controlled laser process.

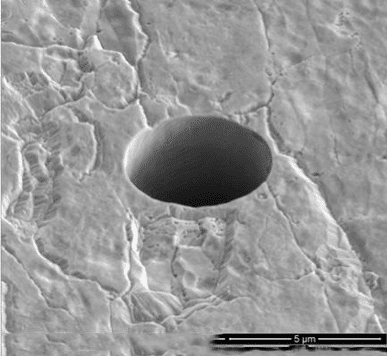

Laser Drilling

Lasers have no tool wear, making the technology ideally suited for high repetition processing. Demanding environments, such as the automotive, medical, and semiconductor markets are clamouring for this technology. With the correct wavelength pulse energy and optics, the reproducibility is astonishing. Filters, flow control, orifices, restrictors, and optical filters are examples of domains with needs for high repeatability in terms of quality and positioning. Micro laser drilling meets this demand perfectly.

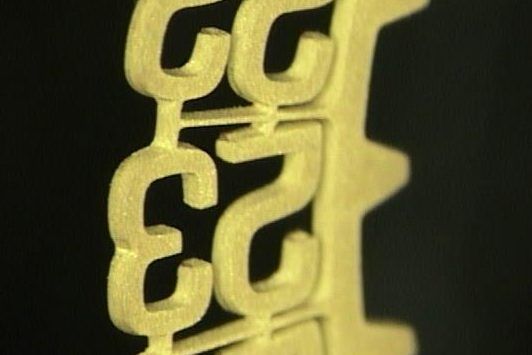

Laser Cutting

From 5 µm up to 2 mm, micro laser cutting combines speed and precision to cut, for example, thin polymers. Depending on the technical or financial reasons, we can choose between long pulse cutting or cutting by ablation. Ophthalmic instruments, sheet metal parts for system integration, and mechatronics are our daily business. We produce various medical instruments where all disciplines are used.

Contact Us

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Lasertec